News

- Home

- News

New certificates

We continue on our ecological and sustainable path and now present our environmental certification according to DIN ISO 14001:2015 and also our current certificate for DIN ISO 9001:2015!

Time-lapse video delivery and assembly

The delivery and installation of our new press line in a time-lapse video. The facts about the new line: Manufacturer: Sangiacomo Press type: T-315 DM-DBV Pressing force: 315 tons Table size: 2,550 x 1,400 mm Machine weight: 54,100 kg

TopCompany – Our employees (m/f/d)

In addition to our modern machinery, another important factor is decisive: Our employees (m/f/d)! We are proud to call ourselves a “TopCompany” thanks to the many positive employee evaluations! We owe this award to the positive feedback and also the…

Delivery of new press line

Following the conversion of the entire hall lighting to energy-saving LED lights and the installation of the 196,000 kWh solar power system, Schulz Stanztechnik GmbH has now made another investment. This is the largest investment in the company’s history to…

Messen 2022

Besuchen Sie uns auf: LOGISTICS & DISTRIBUTION DORTMUND Regionale Fachmesse für die Intralogistik und Materialfluss 18.05. – 19.05.2022 Stand: A17-4 Weitere Informationen: https://www.intralogistik-dortmund.de/ LogiMAT 2022 Internationale Fachmesse für Intralogistik-Lösungen und Prozessmanagement in Stuttgart 31.05. – 02.06.2022 Halle: 1 / Stand:…

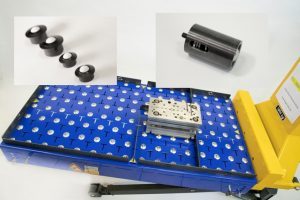

Our SUTTY family continues to grow!

In addition to the standard SUTTY, the SUTTY XL, there is now also the SUTTY XL²! The SUTTY XL² is characterised by its size of 1200×800 mm and the removable fork pockets. This means that it is now possible, for…

Thank you & Merry Christmas

Dear Business Partners, Another turbulent and unusual year is coming to an end. We would like to take this as an opportunity to pause for a moment and reflect. In doing so, we would like to expressly thank you for…

Zutritt- und Besuchsregeln

Wir haben aufgrund der aktuellen Fallzahlen unsere Zugang- bzw. Besuchsregeln im Werk Halver angepasst. Sie können sich ab sofort digital bei uns an- und abmelden mit der App mindful! Diese ist als download erhältlich: Android: https://play.google.com/store/apps/details?id=io.mindnow.mindful&hl=gsw&gl=US IOS: https://apps.apple.com/ch/app/mindful-check-in/id1512941002 Es ist…

Neue Vertretung in Portugal

Ab sofort steht unseren Kunden in Portugal vor Ort folgende Vertretung mit Rat und Tat zur Verfügung: C&P ENGINEERING PROCUREMENT, LDARua do Tronco, Nº 375 – A 0.9PT-4465-275 São Mamede InfestaTelefon: +351 91 251 40 42web: www.cep-ep.ptemail: jorge@cep-ep.pt Bildquellen:Bild von Peggy und…

Schulz ist GRÜN!

Durch die Umstellung unserer Beleuchtung auf modernste LED-Technik im Werk Halver verringern wir den CO2 Ausstoss für unsere Fertigung um 25.3310 kg im Jahr! Klimawandel und Klimaschutz sind ein heiß diskutiertes Thema.Ökologisches Handeln, Nachhaltigkeit und unternehmerische Verantwortung sind Begriffe bei…

Das Jahr startet XL

Wir wünschen unseren Geschäftspartnern ein frohes, gesundes und hoffentlich normales neues Jahr! Unser Schulz-Jahr startet direkt XL! Wir erweitern unser SUTTY-Programm und hier ist ab sofort der SUTYY XL (1200×800 mm, mit 1.000 kg Traglast) lieferbar! Weitere Informationen finden Sie…

Danke & Schöne Feiertage

Sehr geehrte Geschäftspartner (m/w/d), ein turbulentes und leider auch aufgrund der Covid-Pandemie historisches Jahr geht zu Ende. Das möchten wir als Anlass zu nehmen, um mal einen Moment inne zu halten und uns zu besinnen. Dabei möchten wir uns ausdrücklich…

NEU – STriMo – DIE TRANSPORTHILFE

Neu bei uns im Programm: STriMo – Schulz Triangle Mover DIE TRANSPORTHILFE Leichte und kompakte Transporthilfe zum Mitnehmen für schnelles und flexibles Transportieren von großen Lasten! Für den Einsatz auf Beton- oder Industrieböden Blockierfreie Lenkung und leichtgängiges Verfahren auch bei…

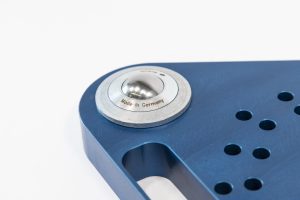

NEU – SMAid – Einschlaghilfe für Schulz-Kugelrollen

Wie kommen eigentlich unsere Schulz Kugelrollen an Ihren “Arbeitsort”? Mit SMAid -Schulz Mounting Aid SMAid hilft Ihnen die Endmontage der Schulz-Kugelrollen sicher, leicht und schnell durchzuführen. Der abrutsch sichere Griff liegt gut in der Hand und die Hand ist zusätzlich…

Sales representative (m/f/d) for products of the conveyor technology wanted

We are looking for a committed sales representative (m/f/d) for our product area “conveyor technology”. We are a manufacturer (please see https://www.schulz-stanztechnik.de/) of ball transfer units, ball roller tables, steel rollers, support rollers and other products for conveyor technology. With…

Ausbau Qualitätssicherung

Nach der Inbetriebnahme unserer neuen Bruderer Schnellläufer-Stanzanlage haben wir speziell für diese kleinen und sehr filigranen Stanzteile in eine weitere “Messmaschine” investiert. Hierzu steht ab sofort ein “Digitaler Messprojektor IM-7010” der Firma Keyence zur Verfügung. Hiermit können wir innerhalb weniger…

Erweiterung Stanzkapazitäten mit Schnellläuferpresse

Wir haben unsere Pressenlinie mit einer Schnellläuferanlage der Fa. Bruderer erweitert – ab sofort können wir für Sie zusätzlich mit folgenden Parametern stanzen: Bruderer Schnellläufer BSTA41 400 KN Druckkraft Hubzahl 100 bis 1.200 Hübe/min Tischfläche 690×550 mm

Desinfektionshalterung

Gemeinsam mit unserem Partner der ÖPNV-Service GmbH haben wir ein Haltesystem zur Händedesinfektion in Bus und Bahn entwickelt! Kurzfristig folgt auch eine Stand-Alone-Lösung für den Einsatz in Hallen, Einkaufszentren usw. . Für Rückfragen und Bestellungen wenden Sie sich bitte direkt…

FAKE Email

Attention: At the moment emails are sent with a request for payment: From: Mario Thomas<thomas.m@schulz-stanztechnik.de> Subject: RE: Payment: Draft TT Wire Transfer Copy – For Your Approval Date: 19 March 2020 at 15:27:45 EET These emails are NOT sent by…

NEW PRODUCTS 2020

Dear customers! The Logimat had to be cancelled due to the Corona epidemic. This year we wanted to present you some novelties at our booth. We will now make up for this with a short and compact video! Here we…

Cancellation Logimat trade fair

The Logimat 2020 has been cancelled, please see the official press release: https://www.logimat-messe.de/en/press/press-releases-downloads/press-releases/press-release-logimat-2020-canceled

Press release on Logimat 2020 – Visit us! Hall 1, booth B36

!! at the moment only in german available !! Pressemitteilung 02 2020

Trade fair Logimat 2020 – Come and visit us!

We look forwad to your visit:

Thanks & Merry Christmas

For the good cooperation and the confidence placed in us in 2019 we would like to thank all customers, suppliers and employees! We wish you and your family a merry christmas day and a happy Start into a healthy and…

Open position as setter/machine operator

For more information: Maschineneinrichter

Social partner program FasiBis – We are there!

“FasiBiS” – Securing skilled workers through education in the stamping and forming industry The FasiBiS project, with the aim of establishing personnel development structures to secure skilled workers in the stamping and forming industry, is financed by the ESF…

Completion of homepage – more languages & information

Our website www.Kugelrollen.de is now available in four languages (German, English, French and Spanish). In addition, we have improved the clarity and provided further information such as data sheets. We are looking forward to your visit on www.Kugelrollen.de !

Schulz Stanztechnik is committed to the future at the Halver location – Press release 02.09.2019

Schulz Stanztechnik GmbH is a specialist for conveyor technology, toolmaking and stamping and forming technology in the field of The Oekinghausen industrial estate continues to invest in the Halver site. On 03.09.2019 a furtherinvestment for the turning technology division of…

New in our program – Spring ball transfer unit, adjustable

New in our program – Spring ball transfer unit, adjustable Our new adjustable ball transfer unit consists of a ball transfer unit with a housing and a cover as solid turned parts, a supporting ball and several supporting balls. Around…

Press report about our company

Our local newspaper Allgemeine Anzeiger (or the corresponding internet platform www.come-on.de) has published a report on our company:

Opening of Logimat 2019

We are here for you from now on! Hall 1, Booth B38 Logimat 2019 in Stuttgart – We are looking forward to your visit!

New company videos for Logimat 2019

The “Making of” of our new corporate videos is currently being implemented by our partner gebauer.media. Just in time for Logimat 2019 we will present our new revised videos! We are looking forward to your visit!

Trade fair – Logimat 2019

Also this year we will exhibit at Logimat 2019 in Stuttgart. Visit us in hall 1, booth B38 to inform yourself about our products and services. You are also welcome to make an appointment with us in advance at info@schulz-stanztechnik.de…

Merry Christmas – Thanks

We would like to thank all our customers and suppliers for the pleasant cooperation in 2018! We wish you a Merry Christmas and a Happy New Year!

New ERP-System

Another important step for the future has now been taken “productively”. Our new ERP system ap+ has now been filled with life together with our system partner et-systems from Limburg. The new system should now help us to further improve…

Ball roller tables according to your wishes

As we manufacture all components around the ball transfer unit in-house, we can of course also respond directly to your special requests. As shown in the example, we have realized a ball roller table with 4 plug-in brackets/stops and a…

Allgäu Round Trip 2018

We would like to thank WNT Deutschland GmbH and Ceratizit Deutschland GmbH for an informative, varied and sporty weekend in Kempten. Here are some impressions:

Machining Training

Further education is very important to us! Today we held a training course on all aspects of machining at our company. Mr. Hans-Jürgen Lange as application technician of WNT Deutschland GmbH informed our employees in a practical, informative and entertaining…

Company Run 2018

In 2018 our team was again present at the company run in Lüdenscheid. At summer temperatures our team enjoyed the run and the following supporting program. To the picture gallery of the Lüdenscheider Nachrichten click HERE!

Virgin ride of our new robot!

Enclosed the virgin- or set-up-ride of our new Dierre Jupiter robot 150N II! We are pleased to manufacture your products with the new robot!

Investment in Quality

We have made another investment in the future and quality. From now on we can measure “your” workpieces using 3D measuring technology. With the device XM1000 of the company Keyence we are able to quickly and accurately control the dimensional…

Thanks for Visit – Logimat 2018

We thank you for the many interesting and nice conversations at the Logimat 2018! Also this year we were able to welcome many “old” acquaintances and many “new” faces on our stand!

New – Ball transfer units and collar

Our solid 15-ball transfer unit with collar is now also completely solid – with massive lid! Further information in the article area!

Thanks for your visit

Thanks to all visitors at the Z 2017 and at the Logimat 2017 for your visit and the interesting discussions! #Logimat #Z #ThanksForVisit